The batching system uses a batching device to accurately weigh various different feed raw materials according to the requirements of the feed formula. The discharge machine, weighing hopper, and weighing hopper gate cooperate with each other under PLC program control to achieve the weighing process.

The weighing process of the system is a continuous feeding process to the weighing hopper. Various materials share a common weighing hopper, and when each material is weighed, the target value and closing value for further weighing are corrected based on the weighing value and closing value of the next material.

After a certain amount of raw material is given, the discharge machine under this ingredient bin stops working, and then the second raw material is dispensed, and the operation is repeated in this way.

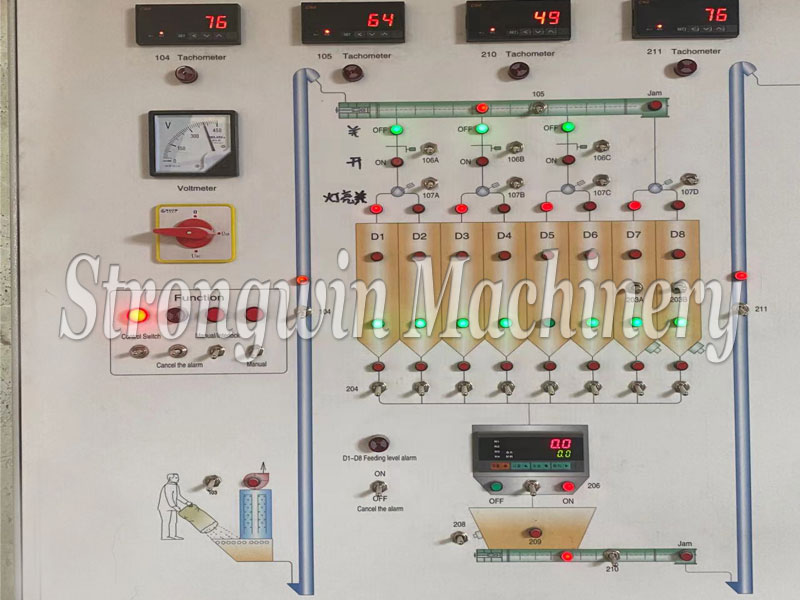

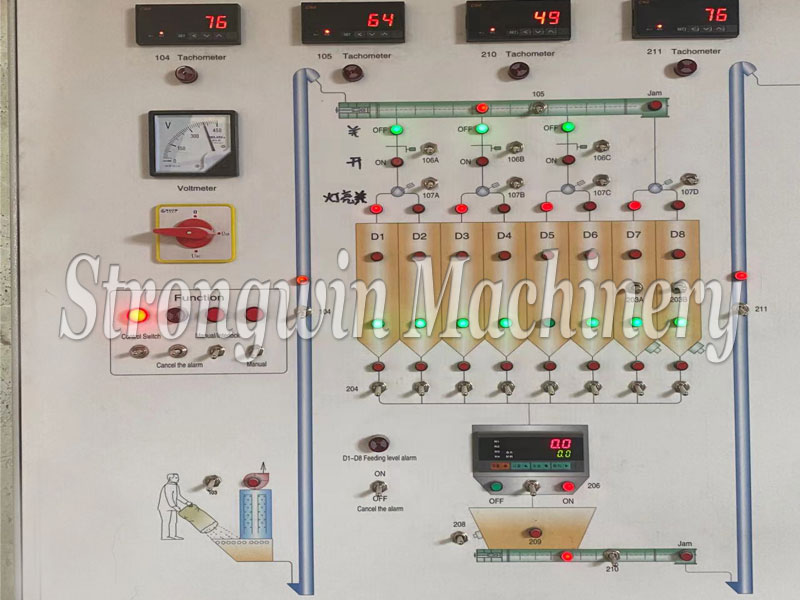

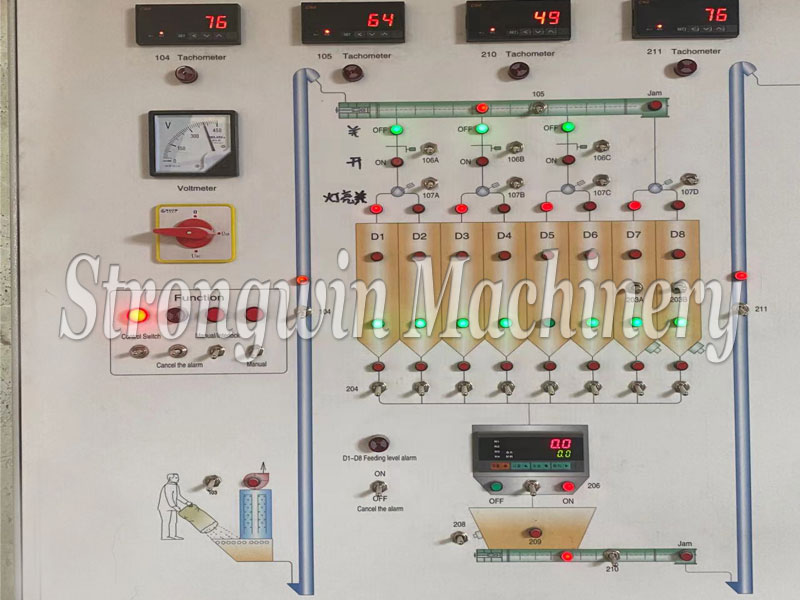

After all the materials are mixed, the computer detects the mixer and receives the material demand signal. It then commands the electromagnetic valve and pneumatic gate to open in a timely manner, allowing the prepared raw materials to flow into the mixer for mixing. The corresponding indicator light on the simulation screen lights up.

At the end of a batching cycle, the computer repeats the above working process. If one raw material exceeds the given range during the batching process, the computer automatically compensates for other raw materials to ensure that the proportion does not change. These operating processes can be displayed on the simulation screen.

It can be used to produce pig feed premix, chicken feed premix, duck feed premix, cattle feed premix, additive premix, etc.

After installation and adjustment,we will train our customers work how to operate;

Training workers on how to maintain and protect.

According to features, we will make complete maintenance rules for you, containing how to maintain, when to maintain, and who maintain

Our company after-sale department will call you at regular intervals, ask if maintain and give advice.